Parts of Reefer Container Explained

A reefer container is a shipping container designed to transport temperature-sensitive cargo, such as food, pharmaceuticals, flowers, and chemicals. Reefer containers have a refrigeration unit that can maintain a precise temperature range inside the container, usually between -30°C and +30°C. Reefer containers are essential for preserving the quality and safety of perishable goods during long-distance transportation.

This blog post will explain the main parts of a reefer container and how they work together to keep the cargo cool and fresh.

Refrigeration Unit

The refrigeration unit is the most critical component of a reefer container. It is responsible for maintaining the required temperature range during transportation. The team uses a refrigerant to absorb heat from the container and expel it outside, cooling it.

The refrigeration unit is located at one end of the container. It has a controller panel allows users to adjust the temperature, ventilation, and humidity settings for specific cargo types. The unit also has a microprocessor that records and monitors the container’s data, such as supply air and return air temperature, defrost activity, power on and off time, etc.

The refrigeration unit can be plugged into an external power source, such as a vessel, a terminal, or a genset on a truck. The power source provides electricity to run the unit’s compressor, fan, and other components.

Insulation

The insulation is another essential part of a reefer container. It is made of polyurethane foam that covers the container’s walls, ceiling, floor, and doors. The insulation helps to reduce heat transfer between the inside and outside of the container and to maintain a stable temperature inside.

The insulation also prevents condensation from forming on the surface of the container, which could damage the cargo or cause corrosion. The insulation is usually coated with stainless steel or aluminium to protect it from moisture and abrasion.

Airflow System

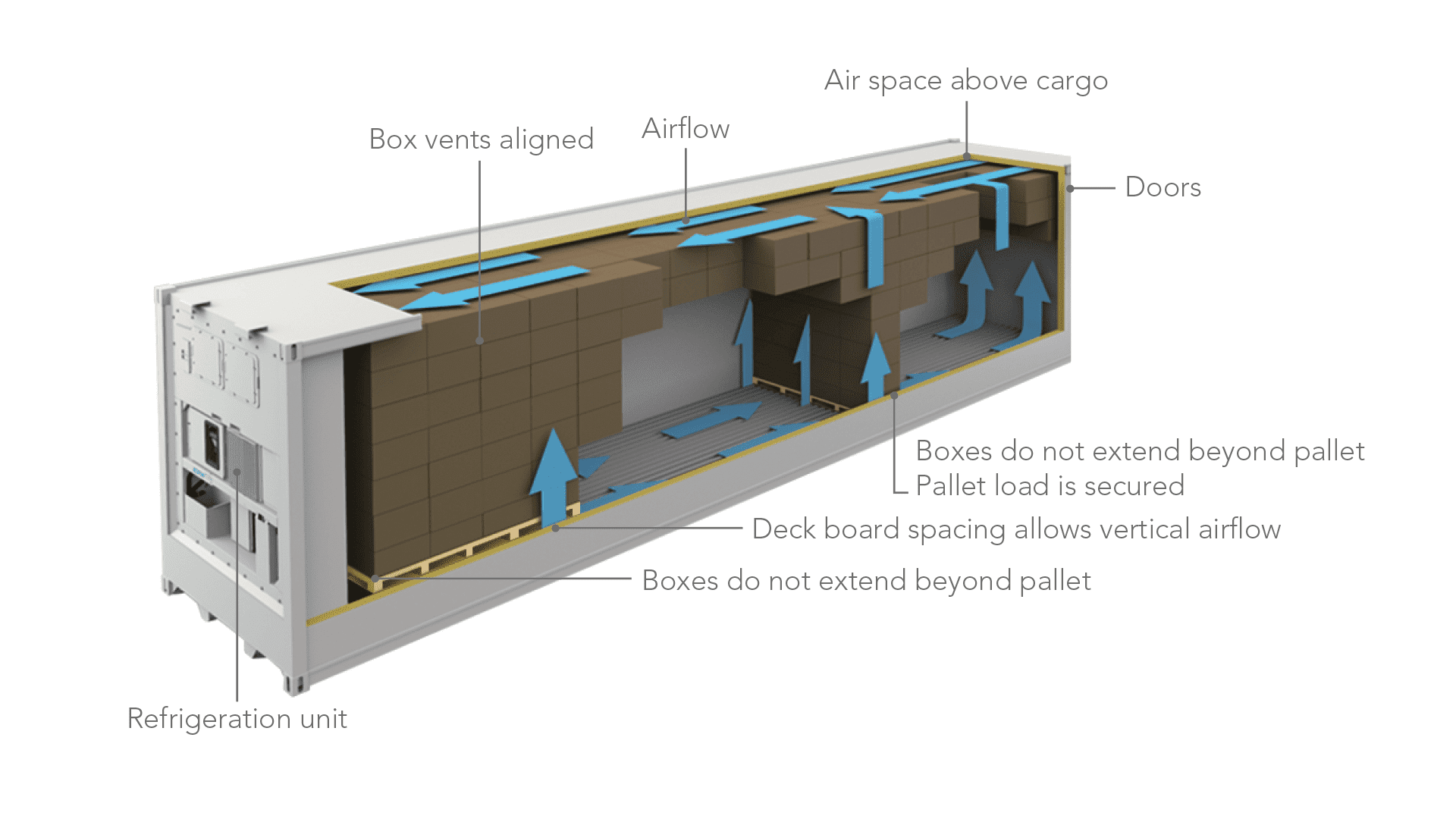

The airflow system is the part of a reefer container that distributes cold air throughout the container and removes heat and gases from the cargo. The airflow system consists of two main elements: the T-shaped floor and the air ducts.

The T-shaped floor is a unique design of the reefer container floor that allows cold air to flow under the cargo unobstructed. The bottom has grooves that create channels for air circulation. The foundation also has drains that release excess water that may accumulate inside the container.

The air ducts are located along the walls or ceiling of the container and have vents that direct cold air into or out of the container. The air ducts are connected to the refrigeration unit, which controls the amount and direction of airflow depending on the cargo type and temperature setting.

Cargo Probes

Cargo probes are optional devices that can measure the temperature of specific shipments inside a reefer container. Cargo probes are cables with a temperature-sensitive element fixed to one end. They can be inserted into boxes or pallets of cargo to monitor their core temperature.

Cargo probes help verify that the cargo has reached or maintained the desired temperature during transportation. They can also help detect any problems or anomalies in the refrigeration or airflow system that could affect the cargo quality.

Cargo probes are connected to the microprocessor of the refrigeration unit, which records and displays their data. Some reefer containers also have an additional monitoring device to transmit the data to an online tracking and tracing system.

Conclusion

Reefer containers are complex and sophisticated devices that enable safe and efficient transportation of temperature-sensitive goods across long distances. They have four main parts: refrigeration unit, insulation, airflow system, and cargo probes. Each piece keeps the cargo cool and fresh throughout its journey.

If you need to ship perishable or sensitive goods, you should consider using reefer containers for your transportation needs. Reefer containers can offer you many benefits, such as:

- Preserving your cargo quality and safety

- Reducing your waste and losses

- Expanding your market reach and opportunities

- Complying with regulations and standards

- Enhancing your reputation and customer satisfaction

To learn more about reefer containers and how to source them at the best price from reliable suppliers, visit SATSCO Containers

عربي

عربي عربي

عربي